What do Risk Mitigation, Quality, and OSHA Have in Common?

Businesses, whether for profit or non-profit organizations, rely on efficient operations to survive. By their nature, businesses create risk.

If we consider the risk to be the exposure to danger, harm, or loss (adverse outcomes). Then we can consider Risk management to be a continuing process to identify, evaluate, and treat loss exposures and monitor risk control and financial resources to mitigate the adverse effects of loss that can prevent the company from achieving its (financial) objectives.

What does this have in common with Quality and OSHA?

All organizations need to verify that their operations are proceeding according to plan. This verification process has many forms and names; however, the objective is the same: verify. Productivity depends on all operations/components coming together in the proper sequence, speed, and quality.

OSHA applies the same concept to ensuring the safety of your employees. We continue to see an increase in OSHA citing standards for General Health and Safety Provisions revolving around accident prevention requiring the employer to establish and maintain programs as necessary. This standard further establishes a requirement for “frequent and regular” inspections. OSHA considers this to be a verification that the prescribed procedures along with the hazard identification and mitigation are understood by the crew performing the task.

Although the standard does not specify the definition of “frequent and regular”, it is increasingly more challenging to overcome such citations once written. Citations can range from $3,500 to $10,000 and will likely carry a serious classification.

What does this mean to employers?

Employers should have:

- Standard procedures

- Training for employees that includes how to perform the task, hazard identification, and mitigation

- Authorization for employees to perform certain tasks (equipment operations, lockout tag out, confined space, excavation, etc.)

- A formal safety meeting process may include monthly, weekly, and daily components.

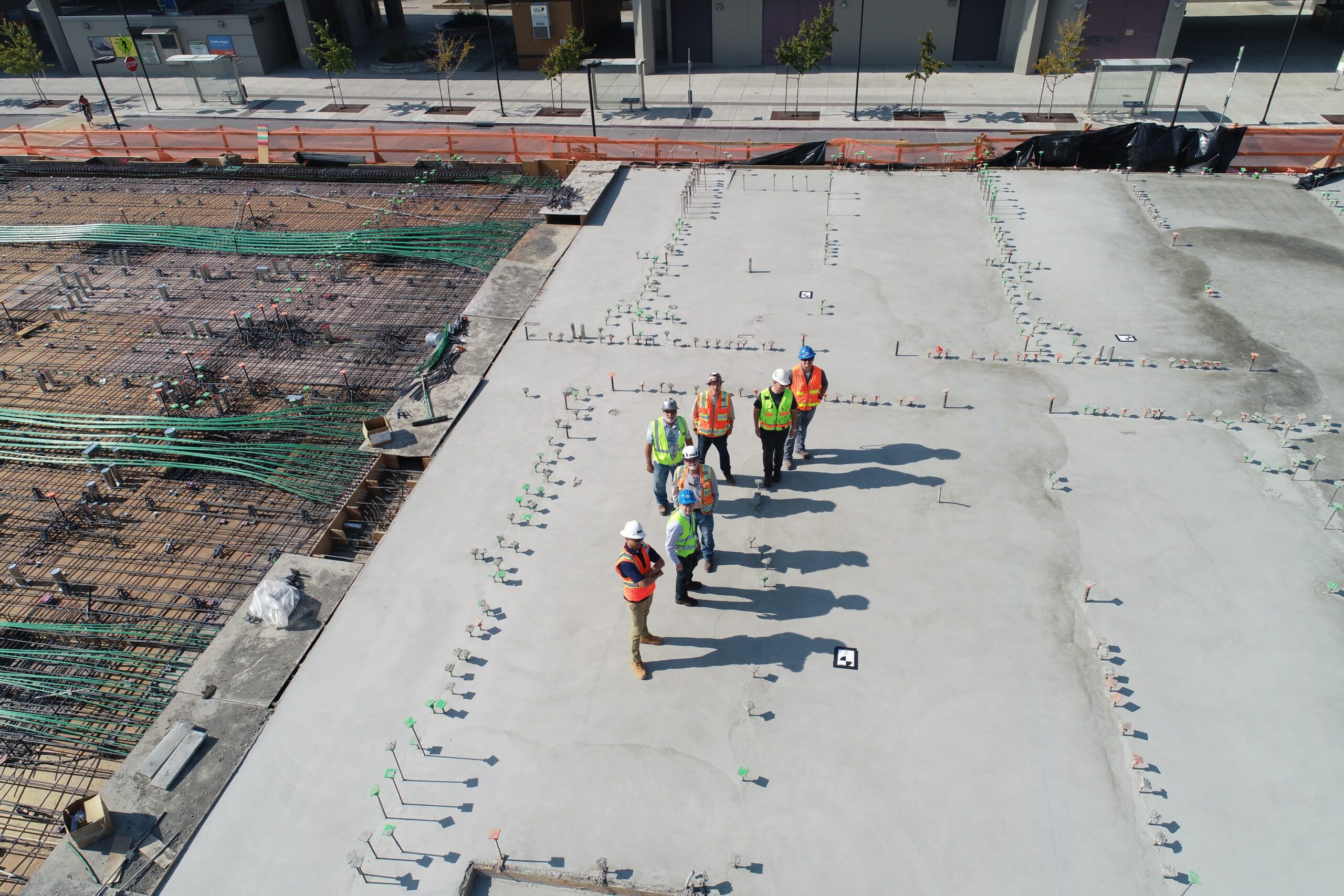

- A verification process (documented). This includes frequent and regular inspections (audits, reviews, verification, etc.)

- Trained, qualified and competent personnel as required by the tasks they are performing, the environment in which they are working, and understand their responsibility to stop and adjust unsafe acts and conditions.

- A method to ensure documented inspections are occurring. This may include combinations of:

- Daily logs

- Focused reviews (audits, inspections, etc.) by site and or company personnel

- Supervisors

- Project Managers

- Safety committees

- Safety personnel

- Management personnel

- Independent third parties

More information on this standard can be found at:

https://www.osha.gov/laws-regs/regulations/standardnumber/1926/1926.20

It should be noted that OSHA will use this, along with other standards such as the General Duty Clause (AKA 5(a)(1), training requirements, and requirements for competent personnel, to write citations.

Your Innovise Risk Control team works to ensure we know your operations so we can assist you with appropriate programs and procedures to better enable you to meet your risk control, quality, and financial objectives and combine Safety, Quality, and Productivity.